Have you ever wondered what a plastering hawk is and how it can make your plastering jobs easier and more efficient? In this article, we will explore the different types of plastering hawks, their purpose, and how to use them effectively. We will also discuss the benefits of using a plastering hawk, common mistakes to avoid, and tips for getting a smooth and even finish. Whether you are a seasoned plasterer or a DIY enthusiast, this article will provide you with valuable insights into the world of plastering hawks.

What Is Plastering?

Rendering is a traditional technique in masonry that involves applying a smooth, flat surface of mortar or cement-based material to interior or exterior walls as a finishing touch.

This process not only enhances the visual appeal of a building but also serves essential functional purposes such as providing insulation and protection against the elements. In the construction industry, rendering is a crucial step that contributes to the overall structural integrity of a building. Craftsmanship and precision play significant roles in achieving a flawless finish, requiring skilled hands to ensure that the plaster is evenly spread and free of imperfections. Attention to detail is paramount, as any errors in application can impact the durability and aesthetics of the final structure.

Explore in-depth: Why Is Venetian Plaster So Expensive

What Is A Plastering Hawk?

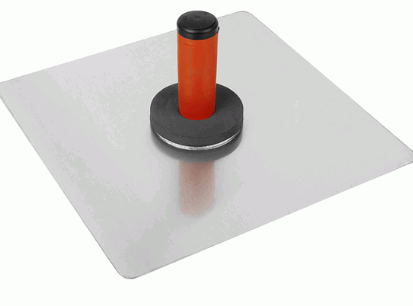

A plastering hawk is a construction tool used by professional skilled laborers in tasks such as plasterwork, drywall finishing, and renovation projects.

This tool consists of a flat, square board known as a hawk board, typically made of metal or plastic, attached to a handle that allows the worker to hold and maneuver it easily. The handle is usually ergonomically designed for a comfortable grip during extended periods of use. Skilled labourers rely on the plastering hawk to hold and transport plaster or mud for application to walls and ceilings, thereby facilitating a smooth and efficient workflow in various construction and renovation settings.

What Is The Purpose Of A Plastering Hawk?

The primary purpose of a plastering hawk is to facilitate the technique of holding plaster for skilled laborers, providing a flat surface for smoothing and enabling precise application with a trowel.

This tool plays a crucial role in the construction process by ensuring that the plaster is easily accessible and ready for application. The hawk’s design allows artisans and experienced workers to control the amount of plaster on the trowel effectively, resulting in a more efficient and uniform finish on walls and ceilings. Its lightweight yet sturdy construction makes it a handy companion for professionals working on various construction sites.

The combination of the hawk and trowel is essential in achieving seamless surfaces and high-quality craftsmanship in plastering projects.

What Are The Different Types Of Plastering Hawks?

There are various types of plastering hawks available, including the traditional wooden plastering hawk and the more durable metal plastering hawk, both essential trade tools for skilled tradespeople and workers.

Each type of hawk serves a specific purpose in the construction industry. The wooden hawk, known for its lightweight and flexibility, is favored by some craftsmen due to its comfort and ease of handling. On the other hand, the metal hawk offers durability and stability, making it ideal for heavy-duty plastering tasks. Skilled tradespeople often carry these hawks in their tool belts, ready to use them efficiently on job sites to achieve smooth and precise finishes. Both wooden and metal hawks play integral roles in achieving professional results in plastering projects.

Wooden Plastering Hawk

The wooden plastering hawk is a classic tool used by skilled contractors and professionals in various construction tasks, particularly for wall plastering and ensuring a seamless plastering process.

With a flat surface and a handle, the plastering hawk allows workers to scoop up plaster or mortar and then apply it to the walls with precision. Its lightweight design makes it easy to maneuver around corners and tight spaces, ensuring that the plaster is evenly distributed. Skilled professionals rely on the plastering hawk to hold small amounts of material at a time, helping them work efficiently without wasting any plaster. This tool is essential for achieving a smooth and polished finish on walls, making it a staple in the arsenal of construction professionals.

Metal Plastering Hawk

The metal plastering hawk is a robust tool ideal for precise plaster application on various surfaces, commonly used by skilled artisans in renovation work and construction tasks within the building trade.

Its sturdy metal construction and flat base makes it easy to hold and manoeuvre, providing a stable platform for mixing and applying plaster. This tool is versatile, allowing artisans to seamlessly work on different wall surfaces such as plasterboard, concrete, or render with efficiency. The metal hawk’s ergonomic design reduces hand fatigue during extended use, enhancing the overall experience for professionals engaged in plastering tasks. With its durability and precision, the metal plastering hawk is a valuable asset for construction projects and renovation works.

How To Use A Plastering Hawk?

Using a plastering hawk involves several steps such as preparing the plaster, loading it onto the hawk, and skillfully applying it with the appropriate tools and equipment for the specific construction task.

To start, ensure that the plaster is of the right consistency – neither too dry nor too wet. This will aid in achieving a smooth finish.

When loading the hawk, use a trowel to scoop up the plaster and transfer it onto the hawk’s surface. Make sure to distribute the plaster evenly on the hawk to prevent it from sliding off during application.

When applying the plaster, hold the hawk securely with one hand and use the trowel in a controlled motion to spread the plaster evenly onto the surface, maintaining a consistent thickness throughout.

Preparing The Plaster

Preparing the plaster is a crucial step in the construction process that requires skillful execution by workers with expertise in building tasks and construction skills.

Properly prepared plaster is essential for ensuring the integrity and longevity of the construction project. Skilled workers must possess a deep understanding of the mixing ratios, consistency, and application techniques to achieve a smooth and durable finish.

Their expertise enables them to troubleshoot issues that may arise during the plastering process, such as uneven surfaces or air bubbles. Without proper preparation, the plaster may not adhere correctly, leading to structural weaknesses or aesthetic flaws.

In essence, the skills and knowledge of experienced construction workers are indispensable for achieving high-quality plaster finishes.

Loading The Plastering Hawk

Loading the plastering hawk efficiently is essential for skilled labourers working on construction sites, ensuring a seamless workflow and precise execution of the construction process in plastering tasks.

Properly preparing the plaster mixture and evenly distributing it on the hawk surface will facilitate smooth application onto walls and ceilings. By strategically placing the plaster on the hawk, workers can minimise wastage and avoid unnecessary spills, ultimately saving time and resources. Maintaining a clean hawk surface is crucial to prevent any contaminants from affecting the quality of the plaster mix. This attention to detail contributes to the overall efficiency of the plastering process and results in a professional finish.

Applying The Plaster

Applying the plaster with precision and expertise is a key task performed by skilled craftsmen and experienced plasterers, crucial in the construction process and various skilled worker tasks.

These craftsmen begin by preparing the surface to ensure it is clean and smooth, removing any debris or imperfections that could affect the plaster’s adhesion. Next, they mix the plaster to the correct consistency before skillfully applying it in even coats using specialised tools. The mastery lies in achieving a seamless finish and ensuring the plaster adheres properly.

Skilled plasterers not only enhance the aesthetics of a structure but also play a vital role in protecting and strengthening walls, ceilings, and other surfaces, making their work indispensable in construction projects and skilled worker assignments.

What Are The Benefits Of Using A Plastering Hawk?

Using a plastering hawk offers various benefits such as easier application of plaster, reducing strain on the wrist and arm, and the ability to achieve a smooth and even finish, particularly valued in the construction industry.

This tool not only enhances the efficiency of applying plaster but also contributes to worker comfort by providing a stable platform to hold and manipulate the plaster. Professionals in the construction industry appreciate how the hawk allows for precise control in spreading and smoothing the plaster, resulting in a high-quality finish that meets industry standards. The balance and control offered by a plastering hawk enable skilled craftsmen to work with greater finesse and accuracy, showcasing their expertise in the art of plastering.

Easier Application Of Plaster

One significant benefit of using a plastering hawk is the easier application of plaster, streamlining tasks in the building trade, and construction work for skilled labour and professionals.

This tool acts as an extension of the skilled worker’s hand, providing a convenient platform to hold and apply plaster effectively. It allows for a smoother and more controlled application, leading to higher precision in finishing work. By using a plastering hawk, professionals can work more efficiently, reducing the time and effort required for each task. Its lightweight design and manoeuvrability make it a practical choice for different plastering jobs, whether in residential renovations, commercial projects, or larger construction sites.

Reduces Strain On Wrist And Arm

Another advantage of using a plastering hawk is that it reduces strain on the wrist and arm, making it a valuable tool in handling plastering materials and equipment for construction tasks performed by skilled tradespeople in the construction trade.

This reduction in strain is particularly beneficial when working on projects that involve continuous application of plaster onto walls or ceilings, as the hawk allows for a more ergonomic position while scooping and spreading the plaster. Skilled tradespeople appreciate the comfort and efficiency that a plastering hawk provides, especially during tasks that require precision and speed. By utilising a hawk, construction professionals can ensure smoother and more controlled application of plaster, resulting in high-quality finishes on their projects.

Creates A Smooth And Even Finish

The use of a plastering hawk enables the creation of a smooth and even finish, essential in tasks performed by skilled workers in renovation projects, wall plastering, and various construction jobs within the building profession.

The plastering hawk serves as a valuable tool for professionals to hold and transport plaster or mortar conveniently while working on walls or ceilings. Its flat surface provides a stable base for workers to scoop up, distribute, and smooth out plaster efficiently. The hawk’s lightweight design makes it easy to manoeuvre, allowing for precise application and minimising fatigue during extended renovation projects. Skilled construction workers rely on the plastering hawk to achieve impeccable finishes, showcasing their expertise and attention to detail in every job.

What Are The Common Mistakes When Using A Plastering Hawk?

Whilst using a plastering hawk, some common mistakes include overloading the hawk with excessive plaster, improper cleaning of the hawk, and using a damaged hawk, negatively impacting construction specialties and building activities.

- Overloading the plastering hawk with an excess amount of plaster can lead to uneven application on surfaces, compromising the smooth finish.

- Neglecting to clean the hawk thoroughly after each use can result in dried plaster buildup, affecting the quality of future work and making the hawk less effective.

- Using a damaged hawk poses risks such as creating uneven edges on plastered surfaces, which can be costly to rectify and may require additional time for corrections, disrupting the overall progress of building projects.

Overloading The Hawk

Overloading the hawk with excessive plaster is a common mistake during a plastering task, affecting the construction process and the efficiency of the plastering method executed by skilled workers and contractors.

This mistake not only hampers the smooth flow of the construction timeline but also leads to the wastage of materials and resources. The excess weight on the hawk can make it challenging for workers to handle, resulting in potential strain injuries. The quality of the plastering work may be compromised, leading to costly rework and delays in project completion.

Skilled workers and contractors need to ensure the proper balance of plaster on the hawk to maintain precision and productivity in the construction process.

Not Cleaning The Hawk Properly

Failing to clean the hawk properly after use is a common error that can affect the longevity of the plastering tool, the efficiency of skilled artisans using it, and the quality of construction tasks involving the equipment and plastering materials.

Regular maintenance not only helps preserve the hawk’s structural integrity but also ensures that it functions optimally during subsequent usage. Clean equipment allows artisans to achieve smoother and more precise plaster applications, enhancing the overall aesthetics of the construction project. A well-maintained hawk contributes to the swift completion of tasks, minimising downtime due to equipment malfunctions. For artisans in the construction industry, the hawk serves as an indispensable tool that must be cared for diligently to uphold work standards and project outcomes.

Using A Damaged Hawk

Employing a damaged hawk in plastering tasks is a common mistake that can hinder the effectiveness of plastering equipment, impact the quality of construction tasks, and pose risks for experienced workers, especially in renovation work handled by skilled tradesmen.

The structural integrity of a hawk directly influences the smooth application of plaster during renovation projects overseen by skilled tradespeople. Using a damaged hawk may lead to uneven plaster distribution, causing inconsistencies in the finish and compromising the overall aesthetics of the project. For experienced workers proficient in renovation works, relying on faulty equipment like a damaged hawk can result in delays and rework, affecting project timelines and budgets negatively.